Bandary PCB production |

||||||||

Files requirement |

Gerber ,protel,powerpcb,autocad ,etc |

|||||||

Materials |

FR-4,Hi-Tg FR-4,lead free materials (RoSH compliant) |

|||||||

CEM-3,CEM-1 |

||||||||

Layer No. |

1-20layers |

|||||||

Board thickness |

0.2mm-5.0mm |

|||||||

Board thickness tolerance |

+/-10% |

|||||||

Copper thickness |

0.5oZ- 5oZ |

|||||||

Impedance control |

+/-10% |

|||||||

Warpage |

0.075-1.5% |

|||||||

Peelable |

0.3mm-0.5mm |

|||||||

Min solder mask dam(a) |

0.125mm |

|||||||

Solder mask clearance(b) |

0.0125mm |

|||||||

Min SMT Pad spacing© |

0.1mm |

|||||||

Solder mask thickness |

0.0.18mm |

|||||||

Hole size |

0.25-6.5mm |

|||||||

Hole size tolerance(+/-) |

+/-0.0762mm |

|||||||

Aspect Ratio |

6:01 |

|||||||

Hole registration |

0.1mm |

|||||||

OSP |

0.2-0.5um |

|||||||

Surface finish |

plating ,goldfinger ,immersion silver ,immersion Tin,OSP |

|||||||

Certificate |

RoSH,ISO9001:2015, UL |

|||||||

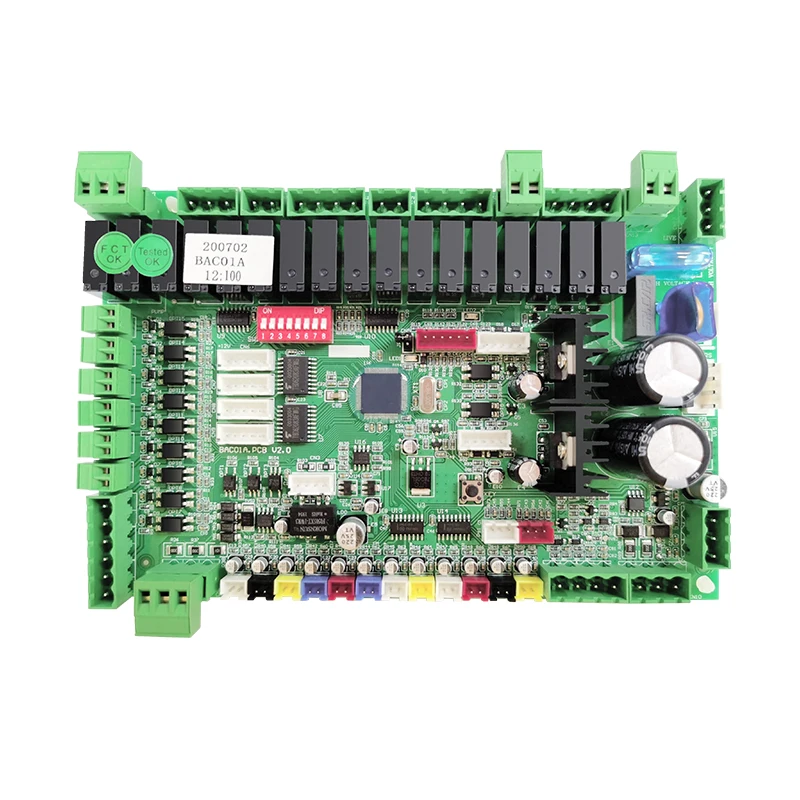

Bandary PCBA production |

||||||||

Professional Surface-mounting and Through-hole soldering Technology |

||||||||

Various sizes like 1206,0805,0603 components SMT technology |

||||||||

ICT(In Circuit Test),FCT(Functional Circuit Test) technology |

||||||||

Aging test ,reliable test (EMC /ESD /slat spary test etc) |

||||||||

PCB Assembly With UL,CE,FCC,Rohs Approval |

||||||||

Nitrogen gas reflow soldering technology for SMT |

||||||||

High Standard SMT&Solder Assembly Line |

||||||||

High density interconnected board placement technology capacity |

||||||||

Gerber File or PCB File for Bare PCB Board Fabrication |

||||||||

Bom(Bill of Material) for Assembly,PNP(Pick and Place file) and Components Position also needed in assembly |

||||||||

To reduce the quote time, please provide us the full part number for each components,Quantity per board also the quantity for orders. |

||||||||

Testing Guide&Function Testing method to ensure the quality to reach nearly 0% scrap rate |

||||||||

PCBA, PCB assembly: SMT & PTH & BGA |

||||||||

PCBA and enclosure design |

||||||||

Components sourcing and purchasing |

||||||||

Quick prototyping |

||||||||

Plastic injection molding |

||||||||

Metal sheet stamping |

||||||||

Final assembly |

||||||||

Test: AOI, In-Circuit Test (ICT), Functional Test (FCT),Reliable test |

||||||||

Custom clearance for material importing and product exporting |

||||||||